Details You’ve Probably Missed

Most drivers never notice the tiny holes staring back at them from road signs. Yet those little punctures tell a story: one of safety, standardization, and a surprisingly clever chapter in the history of modern road design.

Bicycle Clubs And The Birth Of Mounted Signs (1890s)

Long before cars ruled the roads, cycling clubs in England began marking dangerous routes with homemade signs. As they improved stability, drilled mounting holes appeared—primitive, but vital precursors to the modern standard.

Unknown authorUnknown author, Wikimedia Commons

Unknown authorUnknown author, Wikimedia Commons

Auto Clubs Take The Lead (Early 1900s)

In the early 20th century, American auto clubs followed suit by installing embossed metal signs with drilled holes for mounting. Their scattered efforts to mark highways laid the groundwork for later government-standardized signage.

Unknown authorUnknown author, Wikimedia Commons

Unknown authorUnknown author, Wikimedia Commons

Standardized Shapes, Standardized Mounting (1920s)

The Mississippi Valley Association of State Highway Departments revolutionized American road signs by assigning specific shapes—octagons for stop signs and diamonds for warnings. The uniform system helped drivers identify signs instantly, even before reading them.

Federal Highway Administration, Wikimedia Commons

Federal Highway Administration, Wikimedia Commons

Steel U-Channel Innovation (1950s)

By the mid-20th century, engineers had introduced U-channel steel posts with pre-punched slots that enabled faster installation and safer sign mounting. Their efficiency and reliability made them the industry’s workhorse for decades to come.

USA - HOW TO REPLACE ROAD SIGNS, MOVE, CHANGE, REPAIR, MAINTAIN by Master Workers

USA - HOW TO REPLACE ROAD SIGNS, MOVE, CHANGE, REPAIR, MAINTAIN by Master Workers

Painted To Embossed—And Built To Last

Early road signs relied on hand-painted designs that quickly deteriorated due to weathering. Embossed metal lettering, combined with drilled mounting holes, brought durability and visibility. This move advanced roadside safety and sign longevity in equal measure.

Lionel Allorge, Wikimedia Commons

Lionel Allorge, Wikimedia Commons

Breakaway Engineering Takes Shape (1960s–1970s)

As vehicles grew faster, roadside safety demanded change. The Uniform Traffic Control Devices (MUTCD) Manual introduced breakaway post standards with featured predrilled holes engineered to collapse safely on impact. The purpose? To reduce crash fatalities.

Breakaway Signs by Oklahoma Department of Transportation

Breakaway Signs by Oklahoma Department of Transportation

Rural Adaptations And DIY Ingenuity (1970s Wyoming)

Wyoming’s relentless winds once pushed road crews to drill extra holes in signs to keep them from toppling. Although this homegrown tactic became somewhat of a local legend, the so-called “wind perforations” were never formally recognized or adopted as an official engineering standard.

Why Do Some Road Signs Have Holes in Them? by Big Questions

Why Do Some Road Signs Have Holes in Them? by Big Questions

Safety Testing Becomes Science (1980s)

The National Cooperative Highway Research Program (NCHRP) brought crash science to the roadside. Through full-scale vehicle impact studies, Report 350 validated breakaway post designs, setting a modern benchmark for sign safety performance.

SafeSign Breakaway System from Atkore for Highway Road Signs by Atkore

SafeSign Breakaway System from Atkore for Highway Road Signs by Atkore

Federal DOT Wind Load Standards (1990s)

Federal wind load standards from the 1990s—especially the American Association of State Highway and Transportation Officials (AASHTO) guidelines of 1994—reshaped road sign design. Engineers began addressing extreme gusts and dynamic pressure by adopting perforated panels for enhanced stability and longevity.

Highway sign falls during high winds by News 5 Cleveland

Highway sign falls during high winds by News 5 Cleveland

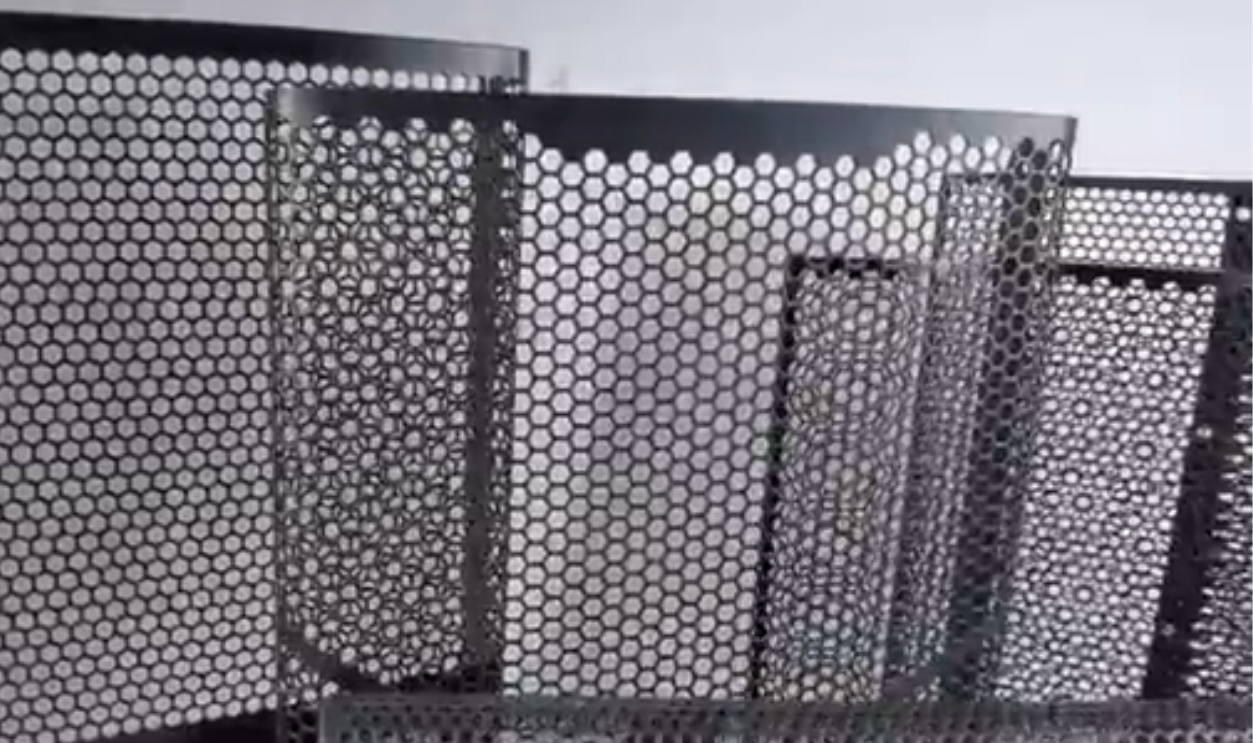

Perforated Signs And Highway Safety

Engineers in the mid-20th century began experimenting with perforated sign panels to help reduce structural stress caused by constant wind exposure. These small holes allowed air to pass through without compromising visibility, effectively preventing signs from bending, snapping, or becoming roadside hazards during storms or high-speed drafts.

Wood Or Steel—Two Paths To Safety

While steel posts dominated highways, wooden ones persisted in rural zones. Engineers began adding controlled breakaway holes to wood supports to provide safer impact responses and ensure that even remote roadways met evolving safety standards.

Finger Post Signs, Wikimedia Commons

Finger Post Signs, Wikimedia Commons

Aluminum Signs Replace Steel (1970s)

As technology advanced, aluminum began to replace heavy steel. The lighter material resisted rust, was easier to perforate, and allowed precision hole placement—making signs both weatherproof and easier to mass-produce using new machining methods.

Tim Evanson, Wikimedia Commons

Tim Evanson, Wikimedia Commons

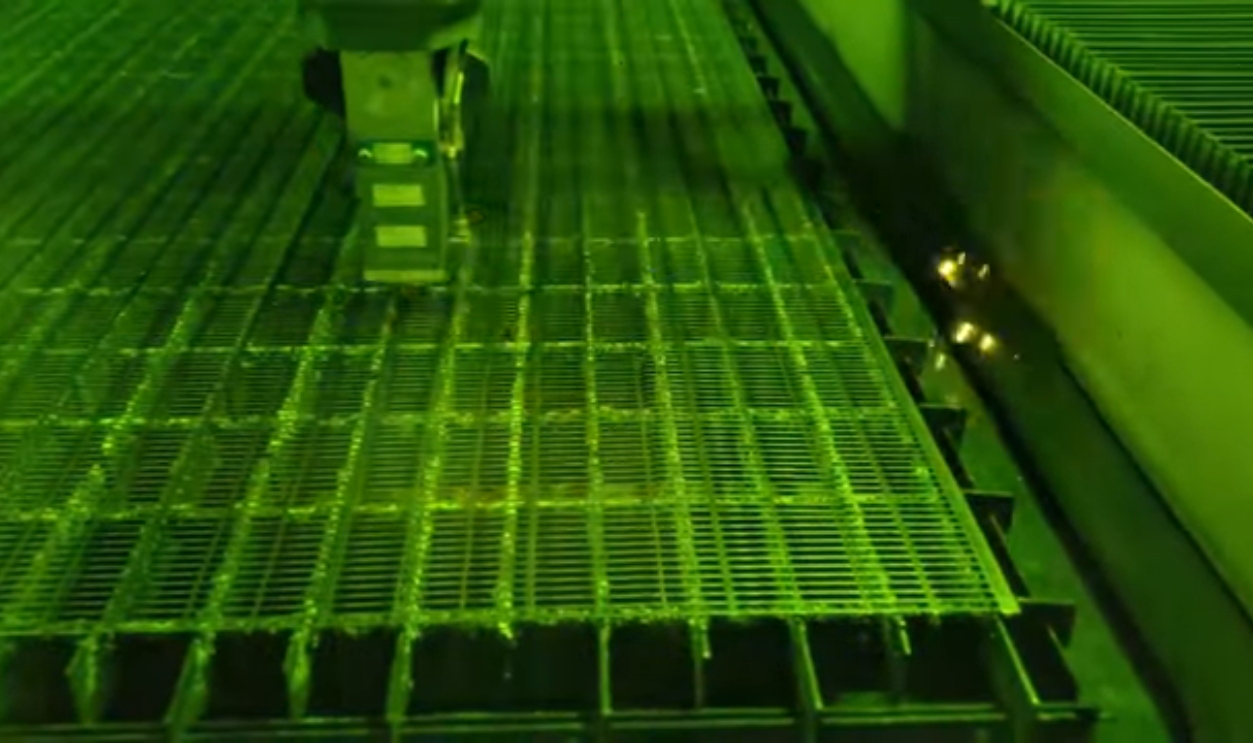

Laser Precision And The Rise Of CNC Cutting

Modern manufacturing changed sign design once more. Laser and CNC cutting machines created uniform perforations with unmatched accuracy to ensure that every hole served structural purposes. This also streamlined large-scale production.

Laser Cutting Sheet of Perforated Steel by Proto G Engineering

Laser Cutting Sheet of Perforated Steel by Proto G Engineering

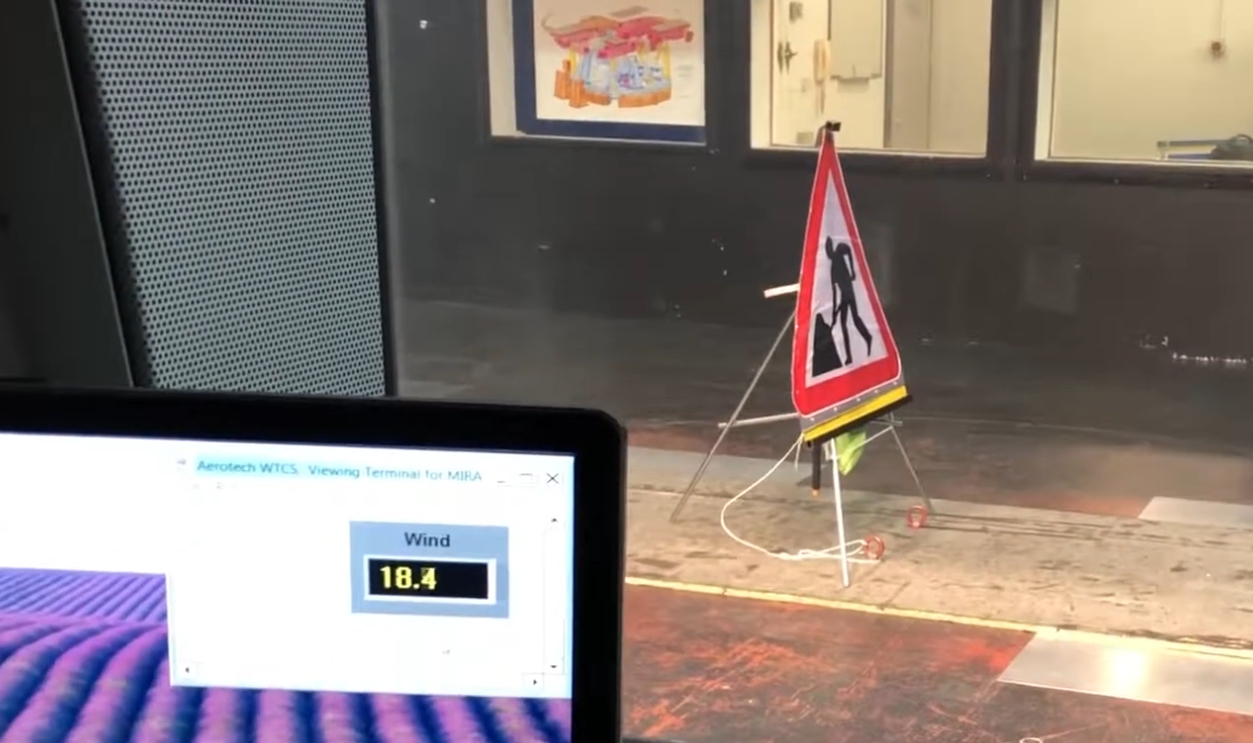

Aerodynamics And Drag Reduction

By the late 20th century, aerodynamic research enhanced sign engineering from trial-and-error to precise science. Through wind tunnel tests, designers discovered how strategically patterned perforations reduced drag and vibration. The result was smoother airflow, longer service life, and increased reliability across environments where wind was a constant adversary.

Wind pressure test on the new road sign by All operating staff

Wind pressure test on the new road sign by All operating staff

Designing For Hurricanes And High Winds

In coastal states like Florida and Louisiana, sign models have changed to meet the demands of hurricane-force winds. Regional Department of Transportation (DOT) adapted sign support standards based on local wind load data and structural safety needs, ensuring critical road signage stayed standing during storms.

PCHS-NJROTC, Wikimedia Commons

PCHS-NJROTC, Wikimedia Commons

Vandalism Hole “Designs”

Away from the structural part of it all, did you know that some hooligans, especially in the rural areas, use road signs for target practice? Oh yes. To combat vandalism, particularly incidents involving gunfire and debris, governments impose fines and penalties on those found to be doing so.

Road sign bullet holes UK!! by spicy110

Road sign bullet holes UK!! by spicy110

Vandalism’s Impact On Structural Integrity

When signs suffer bullet or puncture damage, the impact goes beyond appearance. Even minor holes accelerate corrosion and weaken load-bearing points, ultimately threatening the stability of signs. Highway maintenance crews now rely on corrosion-resistant coatings and modular replacements to mitigate long-term structural fatigue caused by repeated vandalism.

Adoption Of Hole Standards

By the late 20th century, the US had pioneered the use of perforated square steel tubing for signposts. While similar modular designs appeared elsewhere, there’s little evidence that perforated tubing became a formal global standard, as international guidelines prioritize sign visibility and uniform symbols over mounting structures.

CEphoto, Uwe Aranas, Wikimedia Commons

CEphoto, Uwe Aranas, Wikimedia Commons

Breakaway Bases Revolutionize Steel Posts

Modern steel posts now feature engineered bases that absorb crash impact through predesigned joints. This innovation expanded the hole principle—designing for failure to ensure safety—beyond signs to light poles and other roadside structures.

Telespar Sign Post Installation by Strada Sign Supply

Telespar Sign Post Installation by Strada Sign Supply

Wind Tunnel Testing And Computational Modeling

The 21st century brought digital wind studies. Engineers now simulate storm-force conditions using computational fluid dynamics, optimizing perforation layouts to ensure structural integrity while minimizing material waste.

Flexible Sign Wind Tunnel Test by Protect Signs

Flexible Sign Wind Tunnel Test by Protect Signs

Scientific Validation Of Perforations (2020)

A 2020 PLOS One study confirmed what engineers had long suspected: even small holes dramatically reduce wind pressure. Modern simulations provided data-driven proof that historic design instincts had been right all along.

Regional Standards And Local Adjustments

Regional Standards and Local Adjustments Sign hole specifications follow national standards. Departments of Transportation adjust post design using local wind load data, tailoring mounting systems to meet geographic safety requirements.

MASH Standards And The Modern Safety Code (2009–2023)

The AASHTO MASH framework modernized crash testing to ensure breakaway hardware meets stricter impact standards. These guidelines unify decades of engineering progress into the system that governs roadside safety today.

AASHTO MASH Breakaway Safety Test by Frey Manufacturing Corp.

AASHTO MASH Breakaway Safety Test by Frey Manufacturing Corp.

Traffic Lights Join The Movement

The concept of wind perforation expanded beyond road signs in the 1990s to inspire perforated traffic signal heads. These designs allowed high-speed winds to pass through safely, stabilizing intersections in storm-prone areas.

A Century Of Holes, A Legacy Of Safety

What began as a simple way to mount a bicycle warning sign evolved into a global symbol of safety, science, and smart engineering—proof that even the smallest design details can shape how the world moves. So next time you spot holes on a sign during your commute, you know their story.